Driving Excellence and Delivering Measurable Results in a Spinning Unit

Introduction

- A large spinning unit engaged Texcoms to implement an Operational Excellence program across its operations over a period of 6 months. With a capacity of 51,840 spindles producing 100% polyester yarn, the unit sought to address inefficiencies, improve product consistency, and establish sustainable systems.

- The collaboration focused on achieving measurable improvements in productivity, quality, cost-efficiency, and equipment utilization through a structured, data-driven approach.

Problem Statement

The spinning unit was facing several operational challenges that hindered overall efficiency and profitability:

- Inconsistent productivity levels across departments.

- High levels of production waste and energy consumption.

- Variations in yarn quality parameters.

- Absence of standardized operating procedures (SOPs).

- Skill gaps among operational staff and technicians.

- Reactive maintenance practices affecting equipment uptime.

Action Taken

Key Interventions and Operational Enhancements

Mixing SOP & Training

- Soft wastecut before mixing.

- Team trained to follow SOP for soft waste use.

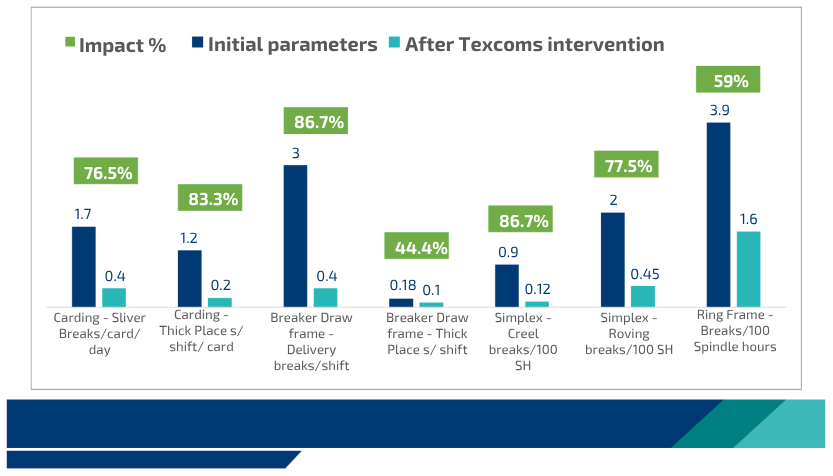

Simplex & Roving Tension Control

- Tension control improved

- Lower creel tension

- Worn-out aprons replaced

- Flyer cleaned regularly

- Piecing reduced with batch creeling

- Better piecing method adopted

Blowroom System Optimization

- Consistent feed through Unimix.

- Smaller tuft size from bale plucker.

- Suction pressure adjusted properly.

- Heavy particle separator SOP applied.

Ring Frame Productivity Boost

- Spindle speed optimized

- SOPs followed for piecing and patrol

- Faulty spindles and lashing fixed

- Drafting and other key areas cleaned

Carding Improvements

- Machine settingscorrected.

- Suction and delivery tuned.

- Damaged parts replaced.

- Coiler cleaning improved.

- Faulty cards fixed.

- Sliver thickness issues corrected.

Link Coner & Quality Monitoring

- Highcuts traced andfixed.

- Bobbin rejection issue corrected.

- Tension and speed fine-tuned.

- Reduced variation between drums.

Draw Frame Enhancements

- Suction pressureadjusted.

- Better sliver joining and batch creeling.

- Cleaning improved in draft zone.

- Hooter cleaning organized.

- Process settings made consistent.

Sustainability & Standardization

- SOPs standardized across units

- Cleanliness routines followed

- Fixed cleaning schedule for key machines

- Regular training for staff

- Machine settings made consistent

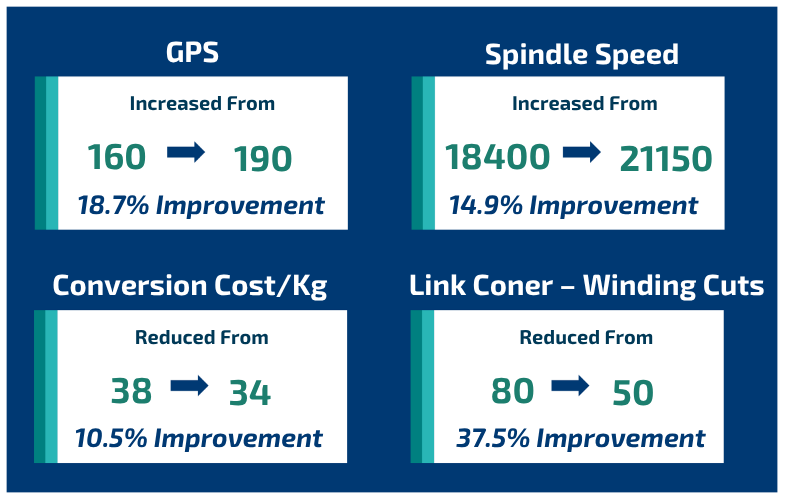

Key Milestones

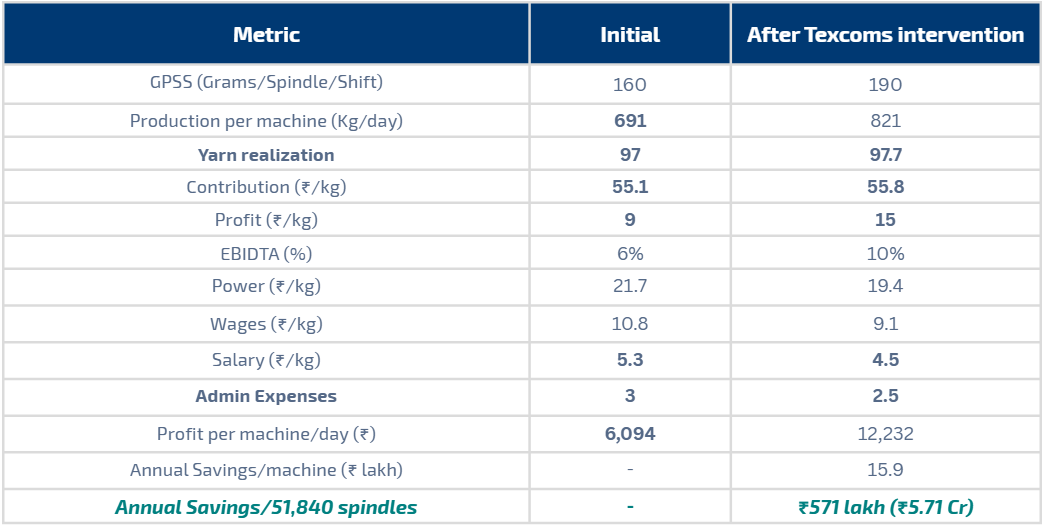

Cost Impact - The Numbers Behind the Transformation

- Unit Profile: 51,840 Spindles.

- Average Count: 40s (100% PSF).

Conclusion

In today's cost-sensitive environment, Texcoms demonstrates thatOperational Excellence is not a one-time fix, but a long-termcommitment to profitability, quality, and sustainability. With deep expertise in machine optimization, process improvement, and operational support, Texcoms enabled the factory to achieve substantial gains in efficiency and product quality-setting new benchmarks in spinning performance.

Talk to our consultants to learn how Texcoms can drive similar results for your organisation.