We assess the machinery and facility as part of our textile machinery inspection services to ensure technical, operational, and commercial clarity before purchase or relocation

- On-site machine inspection and technical evaluation.

- Fixed asset valuation and report preparation.

- Feasibility study and recommended improvement plan.

Safe textile machinery dismantling and professional packing to ensure damage-free movement

- Structured dismantling with tagging for quick re-assembly.

- Protective packing using export-grade material.

- Component-wise documentation and loading supervision.

- Safety compliance for high-value electronic and control panel parts.

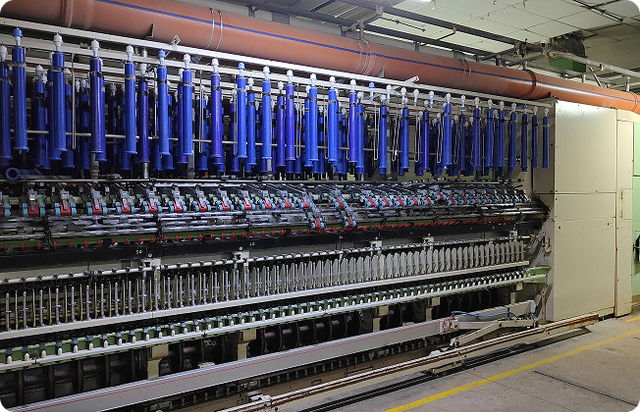

Machines are serviced and upgraded to improve quality, production, and sustainability through textile machinery refurbishment

- Mechanical overhauling, carding machine repair, PCB servicing, and electronic repair.

- Modernisation services (inverter conversion, pneumafil conversion, gearbox to inverter drive).

- Quality optimisation of machinery (blow room, carding, combing, draw frames, speed frame,ring frame, open end, autoconer, & weaving machines).

- Replacement of consumables, rollers, top arms, sensors, utility components, etc.

- Trial running and basic performance validation before dispatch.

We provide complete end-to-end logistics support for both domestic and international cargo

- Import and export logistics solutions for international trade.

- Expertise in commercial documentation and Letter of Credit (LC) handling for cross country transactions.

- International freight forwarding and transportation arrangements.

- Statutory compliance with DGFT / SEZ / FTWZ regulations.

Guidance to optimise project CAPEX and financing structure

- Cost optimisation for existing spinning or weaving projects.

- Project Valuation report support for bank loan processing.

- CAPEX planning and project payback advisory.

- Guidance on subsidy utilisation or incentive documentation.

- Vendor comparison and procurement cost benchmarking.

Seamless textile machinery installation services by experienced technologists

- Erection of machinery from blow room to ring spinning, and weaving looms (airjet / rapier / projectile).

- Calibration of process parameters for stable quality and production.

- Utility connections: compressed air, electrical, AC & waste collection.

- Trial runs and quality validation until target KPIs are achieved.

- Production stabilisation and handover to customer team.

Equipping customer teams to independently run machines with optimum production and quality

- Hands-on operator and technician training.

- Preventive and predictive maintenance guidance is provided during the textile machinery after-sales training.

- Troubleshooting checklist for machine downtime reduction is also covered as part of our textile machinery maintenance support.

Technical consulting to improve efficiency, profitability, and sustainability

- Master plan layout, machine plan, and utility design (spinning & weaving) are provided under our textile machinery consultancy services.

- Gap analysis vs. industry standards (performance, efficiency, energy usage).

- Energy audit and compressed air audit with actionable improvement plan.

- Productivity and EBITDA improvement projects.

Thank you for contacting us . We will get back to you as soon as possible