Tired of falling short on productivity, realization, and seeing profits slip despite your best efforts?

Texcoms optimizes your operations end-to-end, boosting efficiency, reducing waste, and improving EBIDTA and ROI.

Texcoms optimizes your operations end-to-end, boosting efficiency, reducing waste, and improving profitability (EBITDA) and ROI.

Is your textile business struggling with low productivity, operational challenges, and low profitability?

Tired of falling short on productivity, realization, and seeing profits slip despite your best efforts?

Texcoms optimizes your operations end-to-end, boosting efficiency, reducing waste, and improving EBIDTA and ROI.

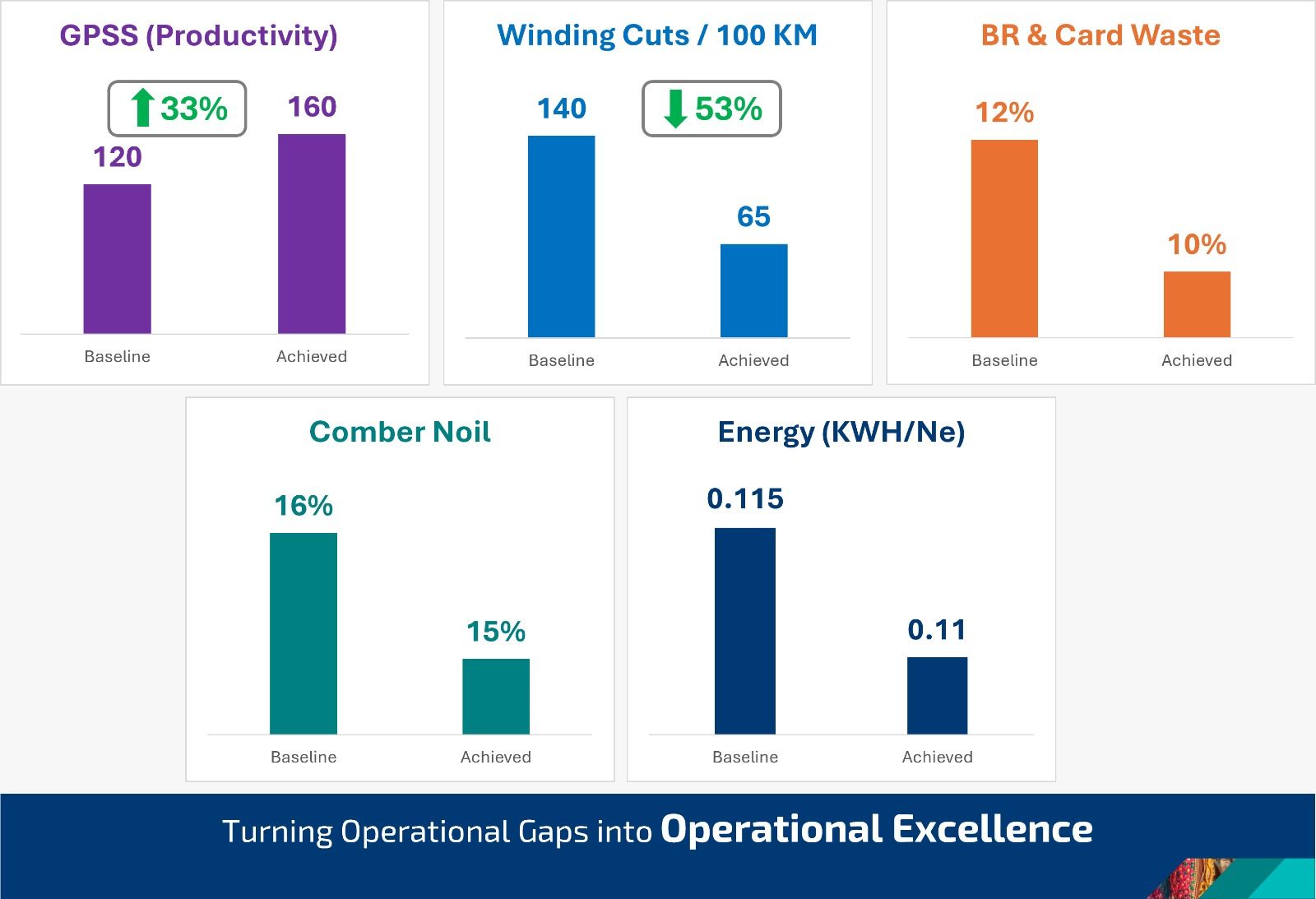

We helped a 50,000-spindle spinning unit increase output by ~33% in 6 months.

Turning Operational Gaps into Operational Excellence

Turning Operational Gaps into Operational Excellence

Even top-performing plants often lose 20–30% of their potential output due to hidden inefficiencies across machinery, process flows, and workforce utilization.

Texcoms identifies bottlenecks, reduces waste, and improves ROI & EBITDA, end-to-end.

Talk to a Texcoms expert today!

Our Proven Path to

Operational Excellence

Our Proven Path to Operational Excellence

Steps:

- Assess: Comprehensive diagnostic study using proprietary benchmarks to uncover hidden inefficiencies.

- Optimize: Production planning, cost optimization, process tuning.

- Implement: On-ground execution, workforce alignment, and KPI tracking.

- Sustain: Establish SOPs, dashboards, and continuous training to maintain gains.

Consulting Function Basket of Services

Performance Assessment & Cost Optimization

Identifying inefficiencies, optimizing resource utilization, and implementing cost-effective strategies for profitability.

- Pre-assessment of existing operations and diagnostic studies.

- Performance benchmarking to compare industry best practices.

- Cost analysis, optimization, and right product mix identification.

- Cost-benefit analysis, and scenario-based cost simulations.

Process Improvement & Operational Efficiency

Enhancing production efficiency, minimizing waste, and ensuring consistent quality for sustainable growth.

- Targeted improvement services (energy audits, waste reduction, realization).

- Deployment of service engineers for troubleshooting and problem resolution.

- Implementing KPIs to monitor operational efficiency.

- Ensuring consistent production quality through QMS.

- Developing and executing operational and financial budgets.

- Achieving year-on-year productivity improvements.

Restructuring & Business Process Re-Engineering

Revitalizing underperforming or distressed assets to restore profitability and modernizing workflows for future readiness.

- Rehabilitation and restructuring of underperforming textile units.

- Revival of non-performing assets (NPAs) for financial institutions.

- End-to-end business process re-engineering.

- Transforming facilities through equipment upgrades.

Large-Scale Project Execution & Operational Management

Executing complex projects seamlessly, from relocation to operational management.

- Relocation of textile factories and turnkey project management.

- Implementation partner for operational excellence.

- Comprehensive operations management oversight.

Business Feasibility & Financial Planning

Providing comprehensive financial and economic assessments to guide investment decisions.

- Investment Requirement Analysis.

- Feasibility Studies / Business Plan / Bankable Report.

- Detailed Project Reports (DPRs), Valuation.

- Working Capital & ROI Analysis.

Strategic Expansion & Integration

Helping clients scale through integration, diversification, and operational improvements.

- Integration Planning (Vertical/Horizontal).

- Layout, Procurement, Erection & Commissioning.

- Recruitment and Skill Development.

- Joint Ventures & Acquisition Support.

Project Execution & Monitoring

Ensuring project success through planning, monitoring, and control.

- EPC / Green Field Projects.

- Schedule & Installation Monitoring.

- Auditing & Corrective Actions.

Growth-Oriented Advisory

Serving as a trusted advisor for strategic growth opportunities.

- Joint Ventures & Acquisition Opportunities.

- Business Valuation for M&A.

- Creating affordable service modules for operational excellence.

Consulting Function

Basket of Services

- 01 Performance Assessment & Cost Optimization

- 02 Process Improvement & Operational Efficiency

- 03 Restructuring & Business Process Re-Engineering

- 04 Large-Scale Project Execution & Operational Management

- 05 Business Feasibility & Financial Planning

- 06 Strategic Expansion & Integration

- 07 Project Execution & Monitoring

- 08 Growth-Oriented Advisory

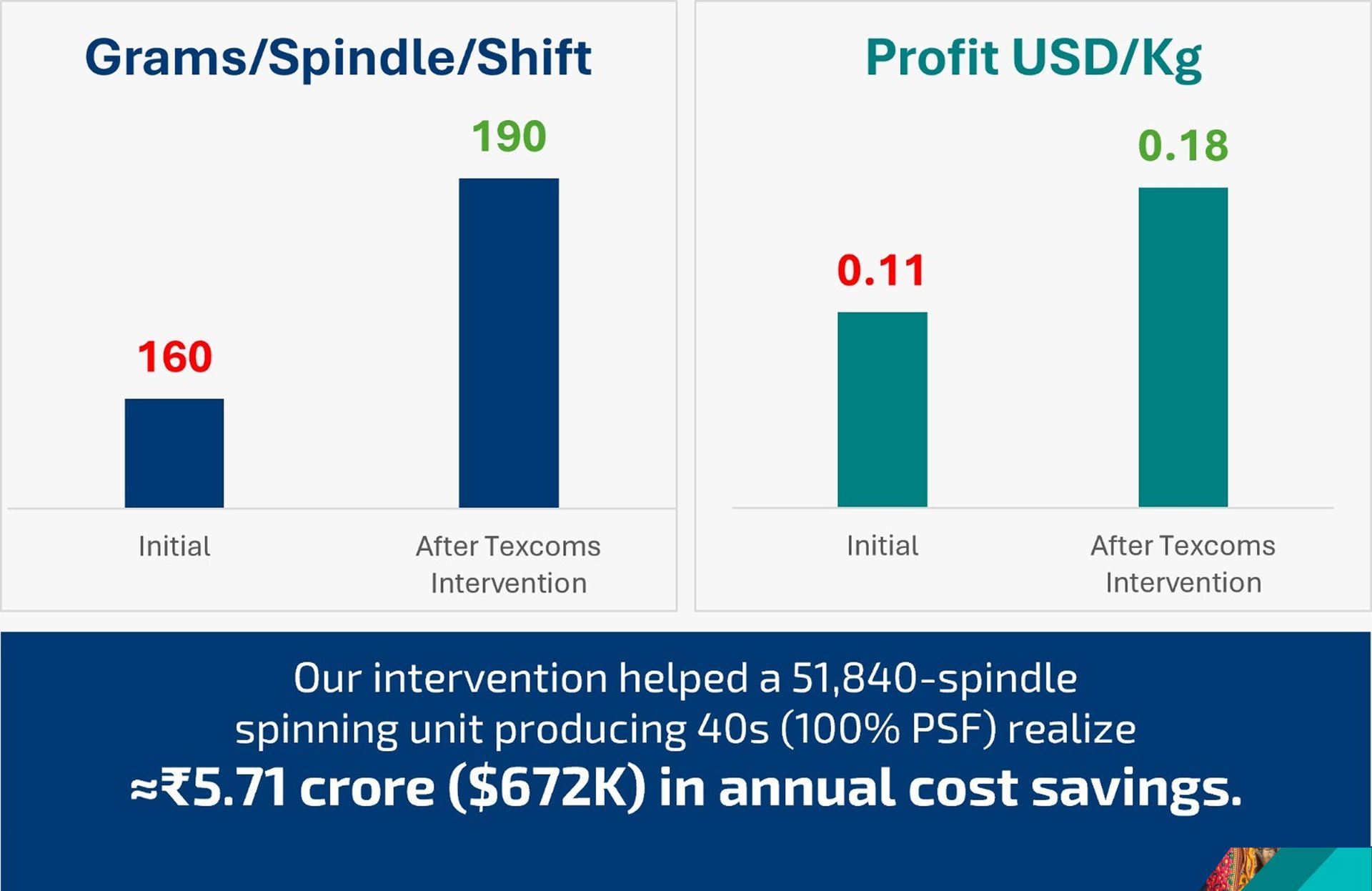

Transforming Spinning Efficiency : A Success Story in Operational Excellence

Transforming Spinning Efficiency : A Success Story in Operational Excellence

Challenge: Inefficient production hindering production targets and compromising quality standards.

0+

Experts worldwide

0+

Customers Worldwide

0+

Operational Excellence Projects

300+

Exports world wide

100+

Ops Excellence Projects

3000+

Customers Worldwide

3000+

Customers Worldwide

100+

Ops Excellence Projects

100+

Ops Excellence Projects

300+

Experts Worldwide

100+

Ops Excellence Projects

3000+

Customers Worldwide

300+

Ops Excellence Projects

300+

Exports world wide

3000+

Customers Worldwide

3000+

Customers Worldwide

100+

Ops Excellence Projects

3000+

Customers Worldwide

300+

Experts Worldwide

100+

Ops Excellence Projects

3000+

Customers Worldwide

300+

Ops Excellence Projects

Real Gains. Real Profit. Real Textile Plants.

Texcoms delivers operational transformations that are quantifiable and sustainable. From improving fibre utilization to boosting machine output and optimizing costs, our interventions help textile manufacturers achieve higher productivity, lower waste, and stronger profitability without major new investments.

Real Gains. Real Profit. Real Textile Plants.

Stop Losing Output and Profits and Unlock Your Plant’s True Potential with Texcoms

Stop Losing Output and Profits and Unlock Your Plant’s True Potential with Texcoms

Every day, textile plants lose output, waste fibre, and bleed profits often without realizing it. Texcoms identifies the hidden inefficiencies in your machinery, processes, and workforce, and delivers targeted interventions that boost production, reduce operational expenditure (OpEx), and increase profitability (EBITDA), all without major new investments. Take control of your plant’s performance and turn untapped potential into measurable results.

Trusted by Leading Businesses

1200

Employees

10+

Countries

1200

Employees

What we do

Cable Systems

Slide Title

Slide 2

Slide Title

Cable Systems

Slide Title

A special engineering company

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

A special engineering 1

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Write down your page title here

Page name

Thank you for contacting us.

We’ll get back to you as soon as possible.

Want to boost efficiency, cut costs or grow your business?

We’ll get you there with proven strategies.