Operations Re-engineering of a Spinning Unit

Client Overview

A

Bhopal-based composite spinning unit operating

200,000 compact spindles within a single shed. The mill faced challenges related to high manufacturing costs, inconsistent product quality, and lack of systematic operational practices.

Objective

To re-engineer the spinning operations for

optimizing manufacturing costs, enhancing

productivity and quality, and implementing

best-in-class work practices and operating systems.

Approach and Methodology

1. Gap Analysis and Action Planning

- Conducted a comprehensive assessment of the plant covering machinery, processes, and workforce practices.

- Identified bottlenecks and problem areas across production, quality, and maintenance.

- Developed a detailed action plan focusing on process optimization, material flow, quality improvement, and energy conservation.

2. Implementation Phase

- Executed the action plan across all departments to address key improvement areas.

- Introduced process control systems and operational checkpoints for monitoring consistency and reducing wastage.

- Integrated

data-driven performance monitoring tools for better visibility across departments.

3. Monitoring and Continuous Improvement

- Established a sustained monitoring mechanism to track progress post-implementation.

- Initiated mini-projects focused on further enhancing productivity, quality, and reducing power consumption.

- Periodic reviews ensured long-term stability and continued performance improvement.

4. Training and Knowledge Sharing

- Organized comprehensive training sessions for staff and supervisors to align with new systems and practices.

- Facilitated

knowledge-sharing workshops to build internal capability and ensure sustainable operational excellence.

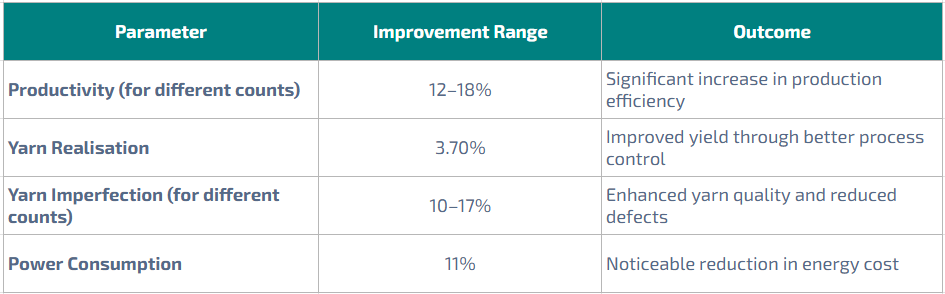

Key Results and Outcomes

- New systems were designed and implemented, specific to the unit’s process flow — from raw material selection to packing of finished goods.

- The introduction of new product lines enabled the unit to achieve better market margins and diversified customer base.

Measured Improvement

Conclusion

Through structured re-engineering, targeted interventions, and workforce engagement, the spinning unit achieved sustainable improvement in operational performance, product quality, and cost efficiency, positioning it competitively within the market.

Talk to our consultants to learn how Texcoms can drive similar results for your organisation.