Strategic Transformation in a Textile Spinning Operation

Background

The spinning industry has been under continuous pressure from rising input costs, global competition, and quality-sensitive buyers. This project was initiated in 2018 with the aim of sustaining competitiveness and improving profitability despite challenges such as increasing labor costs, volatile fuel and electricity prices, and intense market rivalry.

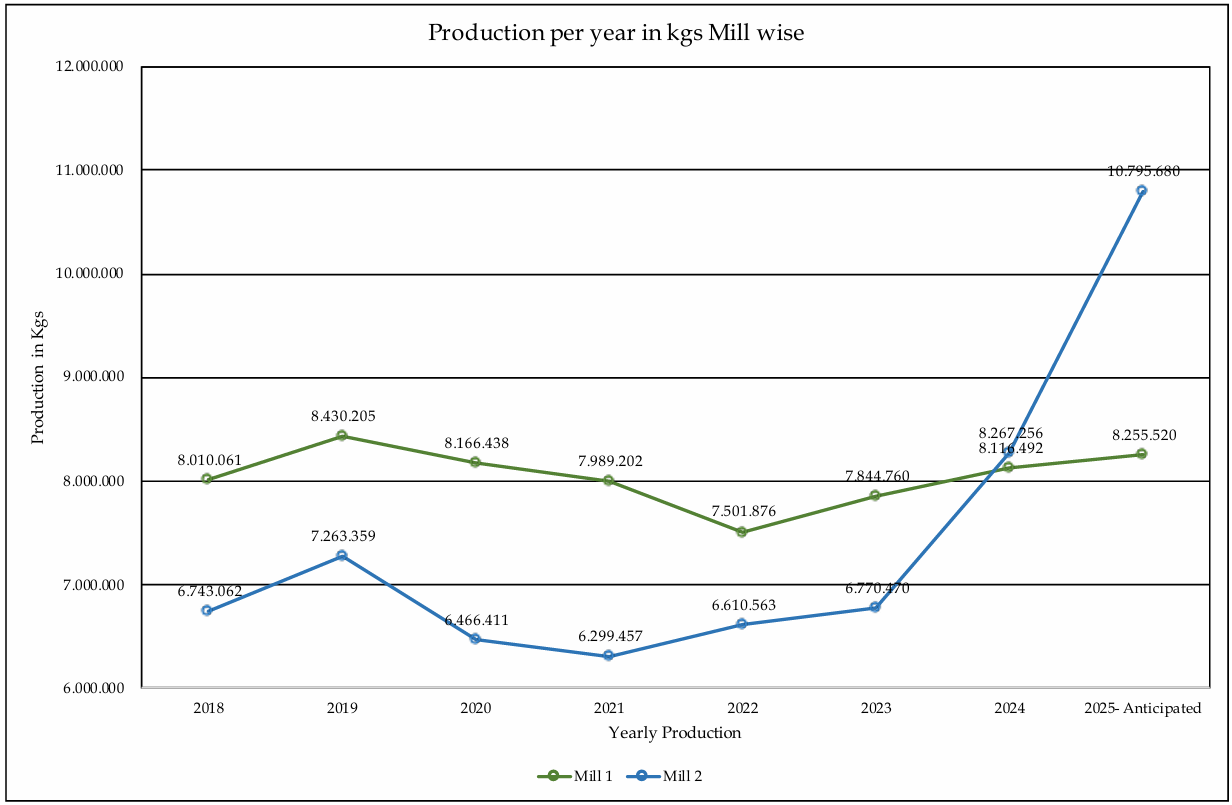

The operation consisted of two mills with a combined spindle capacity of over 60,000. While production was stable, margins were under pressure due to quality gaps and inefficient labor practices. A multi-year roadmap was developed to modernize processes, optimize costs, and shift towards higher-value products.

Objective

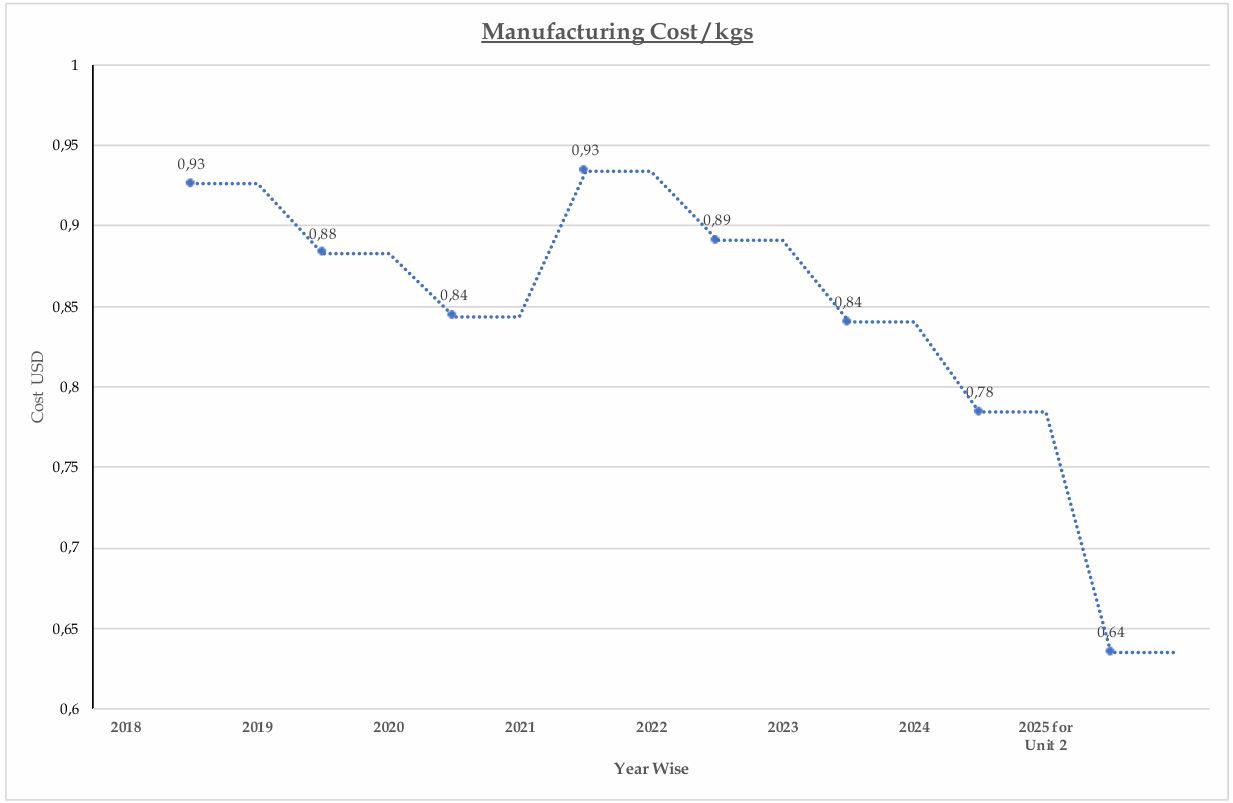

- Maintain or reduce manufacturing cost per bale over a decade despite cost escalations.

- Improve profitability through higher-value combed yarn.

- Enhance product quality to compete with leading suppliers commanding premium prices.

- Reduce manpower dependency and improve operational stability.

- Expand production capacity within existing infrastructure.

Actions Taken

1. Strategic Management

- Transitioned from a disruptive workers’ union to a management-supportive union.

2. Cost Optimization

- Outsourced labor and restructured wage models.

- Savings:

IDR 900 million per month (USD 700,000 per year).

3. Automation Initiatives

- Installed Link Coner, Bobbin Transport, Semi-Auto Packing.

- Reduced manpower by

30%.

4. Capacity Expansion

- Expanded spindle capacity in Mill 2 by 30%.

- Increased production from

7,000 bales/month (2018) to

10,000 bales/month (2025).

5. Product Mix Optimization

Increased focus on combed hosiery yarn:

- 2020: 30% combed yarn

- 2023: 75% combed (Mill 2), 50% combed (Mill 1)

- 2025: 100% combed (Mill 2), 70% combed (Mill 1)

6. Modernization (2018–2025)

Installed new Autoconers, Auto-leveller drawing machines, combers, preparatory machines, and compact spinning lines.

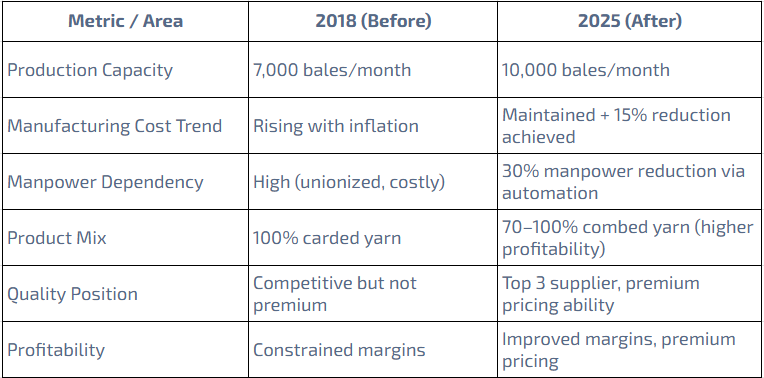

Before vs. After – Transformation Snapshot

Results Achieved

- Cost Discipline: Stable manufacturing cost per bale despite 38% cumulative salary rise and higher energy costs.

- 15% reduction in manufacturing costs achieved over the period.

- Production Growth: From 7,000 to 10,000 bales/month.

- Quality Leadership: Ranked in the top 3 yarn suppliers in the country.

- Profitability: Higher share of combed yarn allowed premium pricing.

- Operational Excellence: Robust systems and modernization enabled long-term scalability.

Key Success Factors

- Clear long-term vision for cost control and product mix.

- Timely adoption of automation.

- Strong management alignment in labor relations.

- Strategic capacity utilization and expansion.

Conclusion

This transformation demonstrates that even in a challenging cost environment, a spinning operation can sustain competitiveness and profitability through strategic management, automation, and product mix optimization. By stabilizing costs, scaling production, and improving quality, the unit successfully transitioned from a cost-pressured operation to one of the top suppliers in the country.

The case highlights the importance of balancing cost control, technology upgrades, and product strategy in building resilience and long-term growth in the textile sector.

Talk to our consultants to learn how Texcoms can drive similar results for your organisation.